Vista Gold Announces Phase 1 Drilling Results at Mt Todd

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240821756858/en/

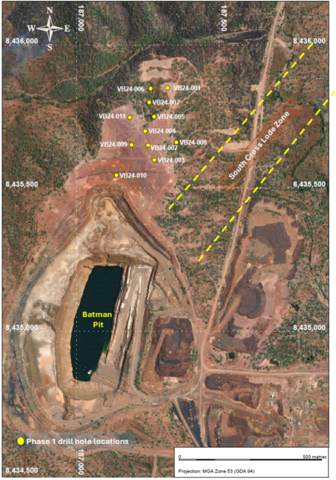

Figure 1 - Plan view of Phase 1 drill hole locations and South Cross Lode zone (Graphic: Business Wire)

Phase 2 of the drilling program commenced in

Please see Figure 1 for a plan view of the Mt Todd as-built terrain, showing Phase 1 drill hole locations and the location of the Southern Cross Lode zone. Figure 2 is a cross section of the northernmost area of the Phase 1 drilling program, including drill holes VB24-001 and VB24-006. Table 1 provides details of the full Phase 1 drill program results.

See Table 1 below for complete intercept details, including true width estimates.

| Hole No. |

Grid Coordinates |

Survey Data |

Intersections |

||||||||||

|

MGA94

|

MGA94

|

RL

|

Azimuth

|

Dip

|

Depth

|

|

From

|

To

|

Interval

|

True

|

Grade

|

Sample Type |

|

|

VB24-001 |

187323.0 |

8435849.0 |

161.0 |

267.6 |

-55.5 |

362.2 |

|

41.0 |

51.0 |

10.0 |

7.8 |

0.62 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

142.0 |

199.5 |

57.5 |

46.0 |

1.17 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

214.0 |

238.0 |

24.0 |

19.4 |

0.54 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-002 |

187252.0 |

8435645.0 |

170.0 |

267.3 |

-53.8 |

341.3 |

|

49.0 |

67.0 |

18.0 |

14.2 |

0.49 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

72.0 |

85.0 |

13.0 |

10.3 |

0.60 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

90.0 |

98.0 |

8.0 |

6.4 |

0.45 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

103.0 |

117.0 |

14.0 |

11.5 |

0.49 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

123.0 |

152.0 |

29.0 |

23.5 |

0.47 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

158.0 |

180.0 |

22.0 |

17.6 |

0.77 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

209.1 |

217.0 |

7.9 |

6.4 |

0.73 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-003 |

187273.0 |

8435597.0 |

171.0 |

266.4 |

-55.0 |

368.3 |

|

53.0 |

60.0 |

7.0 |

5.4 |

0.54 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

87.0 |

107.9 |

20.9 |

16.1 |

1.00 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

166.0 |

175.0 |

9.0 |

7.0 |

0.59 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

183.0 |

219.0 |

36.0 |

28.0 |

0.62 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

249.0 |

267.0 |

18.0 |

14.1 |

0.87 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

272.0 |

280.0 |

8.0 |

6.3 |

0.50 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-004 |

187241.0 |

8435699.0 |

170.0 |

267.6 |

-54.6 |

233.4 |

|

69.0 |

102.0 |

33.0 |

25.5 |

0.50 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-005 |

187267.0 |

8435746.0 |

168.0 |

267.4 |

-57.8 |

290.5 |

|

13.0 |

22.0 |

9.0 |

6.8 |

0.46 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

44.0 |

49.0 |

5.0 |

3.8 |

0.78 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

110.0 |

144.0 |

34.0 |

26.1 |

0.54 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

170.0 |

209.0 |

39.0 |

30.3 |

0.90 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

264.0 |

276.0 |

12.0 |

9.5 |

0.93 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-006 |

187263.0 |

8435844.0 |

150.0 |

275.8 |

-55.3 |

212.0 |

|

51.0 |

88.0 |

37.0 |

29.6 |

0.44 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

93.0 |

102.0 |

9.0 |

7.2 |

0.44 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

110.0 |

113.0 |

3.0 |

2.4 |

0.72 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

118.0 |

127.0 |

9.0 |

7.2 |

0.86 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

132.0 |

145.0 |

13.0 |

10.4 |

0.53 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

192.0 |

195.0 |

3.0 |

2.5 |

0.78 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-007 |

187266.0 |

8435794.0 |

155.0 |

267.1 |

-54.9 |

220.7 |

|

76.0 |

101.0 |

25.0 |

20.1 |

0.49 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

106.0 |

121.0 |

15.0 |

12.2 |

0.47 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

136.0 |

145.0 |

9.0 |

7.4 |

0.55 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

153.0 |

162.0 |

9.0 |

7.4 |

0.48 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-008 |

187346.0 |

8435654.0 |

155.0 |

261.7 |

-55.0 |

422.4 |

|

141.0 |

145.0 |

4.0 |

3.1 |

0.92 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

217.0 |

221.2 |

4.2 |

3.4 |

0.87 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

255.0 |

277.0 |

22.0 |

17.8 |

0.44 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

282.0 |

294.0 |

12.0 |

9.9 |

1.13 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

299.0 |

305.0 |

6.0 |

5.0 |

0.72 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

311.0 |

381.0 |

70.0 |

58.8 |

0.76 |

HQ ½ Core |

|

|

|

|

|

|

|

|

including |

363.6 |

381.0 |

17.4 |

14.6 |

1.51 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

391.0 |

394.0 |

3.0 |

0.8 |

0.81 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

400.0 |

410.0 |

10.0 |

0.5 |

0.45 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-009 |

187194.0 |

8435653.0 |

171.0 |

268.8 |

-57.2 |

210.3 |

|

7.0 |

25.0 |

18.0 |

13.6 |

0.86 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

30.0 |

42.0 |

12.0 |

8.9 |

0.41 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

47.0 |

115.0 |

68.0 |

50.5 |

0.63 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

126.0 |

131.6 |

5.6 |

4.2 |

0.84 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

136.0 |

150.0 |

14.0 |

10.5 |

0.41 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

164.0 |

168.1 |

4.1 |

3.1 |

0.78 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-010 |

187141.0 |

8435542.0 |

162.0 |

274.1 |

-55.1 |

144.8 |

|

0.5 |

9.0 |

8.5 |

6.8 |

0.64 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

55.0 |

67.0 |

12.0 |

9.6 |

0.83 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

92.1 |

124.0 |

31.9 |

25.7 |

0.41 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

129.0 |

134.0 |

5.0 |

4.0 |

0.66 |

HQ ½ Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB24-011 |

187192.0 |

8435746.0 |

179.0 |

269.0 |

-53.0 |

105.4 |

|

2.0 |

9.0 |

7.0 |

5.6 |

0.61 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

14.0 |

21.0 |

7.0 |

5.7 |

0.81 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

27.0 |

42.0 |

15.0 |

12.2 |

0.43 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

68.0 |

72.0 |

4.0 |

3.2 |

0.69 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

76.0 |

79.0 |

3.0 |

2.4 |

0.74 |

HQ ½ Core |

|

|

|

|

|

|

|

|

and |

81.0 |

85.0 |

4.0 |

3.3 |

0.73 |

HQ ½ Core |

|

Notes: |

||

|

(i) |

Results are based on ore grade 50g fire assay for Au. |

|

|

(ii) |

Intersections are from diamond core drilling with half-core samples. |

|

|

(iii) |

Core sample intervals were constrained by geology, alteration or structural boundaries, intervals varied between a minimum of 0.2 meters to a maximum of 1.2 meters. |

|

|

(iv) |

Weighted mean grades have been calculated on a 0.4g Au/t lower cut-off grade with no upper cut-off grade applied, and maximum internal waste of 4.0 meters. |

|

|

(v) |

All intersections are downhole intervals. |

|

|

(vi) |

All downhole deviations have been verified by downhole camera and or downhole gyro. |

|

|

(vii) |

Collar coordinates are given as Map Grid Australia MGA94 using a multi-band GNSS Garmin GPS map 67i. |

|

|

(viii) |

The Company maintains a Quality Assurance and Quality Control procedures (QA/QC) program in accordance with the requirements and guidelines of CIM Standards of Disclosure for Mineral Projects. |

|

|

(ix) |

The independent laboratory responsible for the assays was |

|

QA/QC Protocols and Sampling Procedure

All sampling was conducted under the supervision of the Company's geologists and the chain of custody from Mt Todd facilities to the independent sample preparation facility at

- The core is marked, geologically logged, geotechnically logged, photographed, and sawn into halves using diamond saws. One-half is placed into pre-numbered sample bags as per industry standards with sample lengths between a minimum of 0.2 meters to a maximum of 1.2 meters. The other half of the core is retained for future reference by the company. The only exception to this is when a portion of the remaining core has been flagged for use in metallurgical testwork.

-

Following common industry practices, blanks and standards are also placed in plastic bags for inclusion in the shipment. A reference blank or a standard is inserted at a minimum ratio of 1 in 10 and additional blank samples are added at suspected high-grade intervals. Standard reference material is sourced from

Ore Research & Exploration Pty Ltd and provided in 60 g sealed packets. When a sequence of four samples is completed, they are placed in a shipping bag and tied closed. All of these samples are kept in a secure area on-site until crated for shipping. -

Vista Gold employees ship and transport the samples to the NAL. At the lab, the samples are pulverized and split down to 50-gram assay samples prior to assaying. The industry-standard 3 assay-ton fire assay is followed by an atomic absorption (AA) finish, except where results report a result of greater than 3 g Au/t, and then a gravimetric finish is used to report final results. - For the purposes of this release, mineralized intervals are defined as runs of mineralization with a maximum internal waste of 4.0 meters.

-

NAL is independent of

Vista Gold .

It is the opinion of the QP (as defined below) that the sample preparation methods and quality control measures employed before the dispatch of samples to an analytical or testing laboratory ensured the validity and integrity of samples taken.

For more information on the Company’s

About

Vista holds the Mt Todd gold project, an advanced development-stage gold deposit located in the low risk, Tier-1 mining friendly jurisdiction of

Vista seeks to position Mt Todd among the leading development opportunities within the gold sector. Vista’s strategy is to advance Mt Todd in ways that efficiently position the Project for development while exercising the patience necessary to best realize value at the right time.

Vista expects continued strength in the gold price and believes that shovel-ready projects like Mt Todd will become increasingly crucial for replacing globally declining gold reserves. Vista’s strategy of advancing Mt Todd with discipline and patience is expected to deliver a more fully valued project as markets and the gold industry align.

For further information about Vista or Mt Todd, please contact

Forward Looking Statements

This news release contains forward-looking statements within the meaning of the

View source version on businesswire.com: https://www.businesswire.com/news/home/20240821756858/en/

Vice President of Investor Relations

(720) 981-1185

Source: